Temperature Sensors

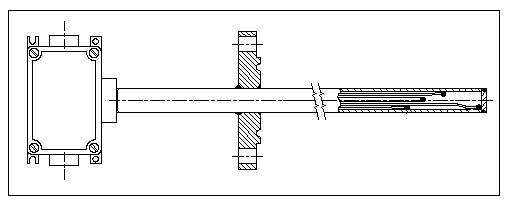

Mineral Insulated Resistance Temperature Detector

A Resistance Temperature Detector (RTD) senses heat, based on the principle, that a change in temperature, results in a corresponding change in the resistance of a wire. A small excitation current is passed along the element, the resultant voltage is measured and converted to units of temperature.

RTDs have achieved a well deserved reputation in various Industries for their superior stability and accuracy. The result makes these devices well suited for a wide variety of applications.

| Technical Specifications | |

|---|---|

| Element | 1 x Pt100 or 2 x Pt100( Simplex or Duplex). ( Any other like Pt 1000, Pt 46 etc on request.) |

| Range | 0 to 500 Deg C |

| Sheath OD | 3.2mm,5mm, 6mm,8mm ( Any other size on request) |

| Sheath Material | SS316, as Standard, SS316L, SS321 on request |

| Insulation | Compact Mgo ( Over99% Purity) for Metal sheathed Type and Ceramic for Beaded Type |

| Calibration STD | IEC-751/DIN 43760( Class A or B) |

| Conductor | Copper for MI type and Silver only for Beaded type, Nickel for MI type on request. |

| Configuration | 2 Wire, 3 Wire, 4 wire |

| Open End | Pot Seal, Plug & Jack, Terminal Block with SS Disc |

| Head | Die Cast Aluminium, SS304,SS316 (Simplex/Duplex) with one or two cable entries. |

| Protection | Weatherproof to IP 67 Flameproof IIA, IIB as per IS/IEC:60079-1:2007. Flameproof IIC as per IS/IEC:60079-1:2007. |

| Cable Entry | ¾" ET, ½" NPT, ¾" NPT( Any other on request) |

| Extension | Nipple Union Nipple assembly In Cd plated Cs,SS304,SS316( Any other on request) Minimum 100 mm but 150mm as a standard .( Any other on Request) : Adjustable Gland( NPT,BSP,) ( Any other on request) In SS304,SS316( Any other on request) : Nipple 75mm/100mm long as standard, any other on request : In Cd plated Cs, SS304 ,SS316 as standard, ( Any other on request) |

| Process Connection: | ½", ¾" as standard.( Any other on request) |

| Accessories | Single/Double Compression Cable Gland in Ni Plated Brass, SS304, SS316( Any Other on Request) : Metallic Plug for Head in Aluminium, SS304, SS316( Any other on Request) |

| Optional | Can be provided with Head/ Remote Mounted Transmitter Can Be provided with all types of Thermowell |

| NOTE FOR BEADED TYPE OF RTD : Resistance Temperature Detectors with Conductors of Silver, in Ceramic Beaded Construction , and packed with MgO powder and encapsulated in a sensing Metallic Tube in SS316.(Any other material on request) can be supplied | |

Some Special RTD Assemblies

Bearing RTDs

Bearing RTDs are designed for areas where there are space limitations. They are small, compact and are often used to detect temperature in bearings, thrust bearing plates, shafts and motor windings. They are miniature low mass sensors which are fast responding.

Bearing sensors are manufactured using thin film technology and by design are tip sensitive and vibration resistant. They can be spring loaded into a bearing housing or held in position with a high temperature epoxy resin. Various types of Fittings including Bayonet can be provided with the assembly. SS braided Cable of varying lengths and Diameters can also be provided as per the requirement.

RTDs with Temperature Transmitters

Temperature Transmitters with or without Local Indication can be supplied with RTD’s and Thermocouples. The TT can either be Head Mounted (Integrated) or Remote Mounted (External).

Such assemblies are provided with Spring Loading arrangement to ensure proper contact. The said assembly is duly calibrated for the Temperature Range as per the requirement.

Winding Temperature RTDs

RTD element is a thin, wide and flat flexible element, specifically designed to be inserted in the windings of a stator of a generator or motor. This is used for measuring the winding Temperature and stopping the system in case of overheating.

These detectors would be embedded into the winding slot and their resistance varies with the temperature

Mineral Insulated Thermocouple

.jpg)

A thermocouple is a device that is used for measuring temperature. It basically consists of two dissimilar metals , that are joined to form a junction, which when heated ,produce a thermoelectric voltage. This voltage changes as the temperature increases or decreases. Thermocouples are self powered and require no external form of excitation. Thermocouples are widely used in science and industry applications include, temperature measurement for kilns, gas turbine exhaust, diesel engines, and other industrial processes

| Technical Specifications | |

|---|---|

| Element | J,K,E,T,N, Type (Simplex or Duplex) |

| Sheath OD | 3mm, 6mm, 8mm, 10mm ( Any other size on request) |

| Sheath Material | SS316,SS321, INC 600, SS310 ( Any other on request) |

| Insulation | Mineral Insulated , Compact Mgo ( Over99% Purity) |

| Calibration STD | IEC-584/ ANSI MC 96.1 ( Class 1 or 2) |

| Junction | Grounded, Ungrounded, Exposed |

| Open End | Pot Seal, Plug & Jack, Terminal Block with SS Disc |

| Head | Die Cast Aluminium, SS304,SS316 (Simplex/Duplex) with one or two cable entries. |

| Protection | Weatherproof to IP 67 Flameproof IIA, IIB as per IS/IEC:60079-1:2007. Flameproof IIC as per IS/IEC:60079-1:2007. |

| Cable Entry | ¾" ET, ½" NPT, ¾" NPT( Any other on request) |

| Extension | Nipple Union Nipple assembly In Cd plated Cs,SS304,SS316( Any other on request) Minimum 100 mm but 150mm as a standard .( Any other on Request) : Adjustable Gland( NPT,BSP,) ( Any other on request) In SS304,SS316( Any other on request) : Nipple 75mm/100mm long as standard, any other on request : In Cd plated Cs, SS304 ,SS316 as standard, ( Any other on request) |

| Process Connection: | ½", ¾" as standard.( Any other on request) |

| Accessories | Single/Double Compression Cable Gland in Ni Plated Brass, SS304, SS316( Any Other on Request) : Metallic Plug for Head in Aluminium, SS304, SS316( Any other on Request) |

| Optional | Can be provided with Head/ Remote Mounted Transmitter Can Be provided with all types of Thermowell |

| NOTE FOR BEADED TYPE OF RTD :1. Normal Ceramic Beaded Thermocouples packed with MgO powder

and encapsulated with sensing metallic Tube can also be supplied. 2. For selection of Thermocouple with respect to temperature please refer our selection chart A and B |

|

High Temperature Suited Thermocouples

High Temperature Thermocouples are especially designed for the temperature range from 600 °C upto 1600 °C. Noble metal thermocouples (also called rare metal thermocouples) are used to make the thermocouples. The most common types are R, S & B rare metal thermocouple assemblies. Major Applications include,Glass Industry,Steel Plants, electric arc furnace etc.

| Technical Specifications | |

|---|---|

| Element | R, S, B ( PtPt Rh Type) (Simplex or Duplex) |

| Sheath OD | 6mm, 8mm, 10mm, 12mm |

| Sheath Material | Inconel 600, SS310 |

| Insulation | Ceramic Beaded , KER 710 Insulation packed with Mgo Powder. |

| Calibration STD | IEC-584/ ANSI MC 96.1 ( Class 1 or 2) |

| Junction | Ungrounded |

| Open End | Terminal Block with SS Disc |

| Head | Die Cast Aluminium, SS304,SS316 (Simplex/Duplex), with One or Two Cable entries |

| Protection | Weatherproof to IP 67 Flameproof IIA, IIB as per IS/IEC:60079-1:2007. Flameproof IIC as per IS/IEC:60079-1:2007. |

| Cable Entry | ¾" ET, ½" NPT, ¾" NPT( Any other on request) |

| Extension | Nipple Union Nipple assembly In Cd plated Cs,SS304,SS316( Any other on request) Minimum 100 mm to 150mm as standard .( Any other on Request) : Adjustable Gland( NPT,BSP,) ( Any other on request) In SS304,SS316( Any other on request) : Nipple 75mm/100mm long as standard, any other on request : In Cd plated Cs, SS304 ,SS316 as standard, ( Any other on request) |

| Process Connection: | ½", ¾" as standard.( Any other on request) |

| Accessories | Single/Double Compression Cable Gland in Ni Plated Brass, SS304, SS316( Any Other on Request) : Metallic Plug for Head in Aluminium, SS304, SS316( Any other on Request) |

| Optional | Can be provided with Head/ Remote Mounted Transmitter Provided with Protecting Tubes made out of a. KER 710 b. Barstock Inconel 600 c. Fabricated in Inconel 600 with sensing portion in Bar stock |

Mineral Insulated Thickwall Thermocouples

| Types of Thermocouple Offered | |

|---|---|

| Element | J ( Iron constantan) K ( Chromel alumel) E ( Chromel constantan) |

| Sheath Material | SS316, SS310, INCONEL 600, INCOLOY 800, SS446 |

| STD Sheath Diameter | 10mm, 12.7mm, 15mm, 17mm,19mm |

Thermocouples are generally used with an outer protecting tube or pocket / thermowell to protect it from corrosive process conditions. This improves the life of the thermocouple. However, response time is compromised.

To overcome above problem, MI Thickwall Thermocouple are designed having thicker wall with relatively larger conductor diameters. This construction enables the user to insert the thermocouple directly in the process medium without a protecting tube or pocket/ thermowell, thus improving the response time to a great extent in some process conditions.

Thickwall thermocouple offers high performance and longer life in harsh process environments, providing improved resistance to temperature, vibration, impact, corrosion and abrasion.

These type of thermocouples, are very well suited to harsh, high temperature process environments such as incinerators, heat treatment furnaces and industrial ovens, and hence can be used effectively for measuring the temperature of molten metal also.

In such type, the gap between the element and the thick wall sheath is densely filled with high purity magnesium oxide (MgO), which prevents any residual air from penetrating the sheath and enables the product to withstand severe conditions, providing excellent corrosion and heat resistance.

This enables faster response times compared to conventional standard thermocouple assembly.. The thermocouple element is protected by the thick wall sheath and high purity magnesium oxide, which can be supplied in large diameters with a very thick wall sheath providing a high resistance to vibration and impact shocks.

Tube Temperature Type Thermocouple

_Type_Thermocouple.jpg)

_Type_Thermocouple2.jpg)

Such Type of thermocouples are ideal for the reliable measurement of tube wall temperatures in fired heaters which is important for prolonging tube life and ensuring safe and efficient operation.

The Tube temperature Thermocouple is designed to be responsive to tube wall temperature by placing the thermo-junction in fused contact with the tube wall thus providing a direct and total metallic heat transfer path from the sheath to the Tube wall. Such type of thermocouples provides better accuracy, superior reliability, improved longevity and ease of installation . Tube or Skin type thermocouples can be designed and factory formed to suit nearly any installation or application based on the clients requirement.

Mounting Types of Tube Thermocouples

Straight

Angular

Expansion Loop

Weld Pads

The weld-pad (tube skin) termination allows a temperature sensor to be welded directly onto piping or other metal surfaces to sense the surface temperature. Weld pads are most commonly used in fired heater tubes, refinery heater tubes, boilers and furnaces in refineries, and industrial boilers. However, they can be used in virtually any application requiring surface temperature measurement. We excel at creating custom designs and engineered solutions to fit your requirements

Choose from a variety of junction styles (knife-edge shaped, transverse shaped, etc.), materials, wrap-around angles, expansion loops, stem lengths, and spring loaded covers. Our weld pads allow severe service temperature measurement with minimum drift and minimum radiant heat impingement. Weld Clamps and Retaining Clips complete the assembly.

Thermocouple and RTD Multipoint Sensing Assemblies.

Quite Often there is a need to measure a temperature profile across a large Tank or Vessel. This can be done effectively by using MultiPoint assemblies which is an arrangement of Thermocouple /RTD positions with measuring junctions at various depths. The purpose is to monitor a number of temperatures at various points with all thermocouples or RTD’s contained in one assembly.

These type of assemblies are used in Catalytic Crackers, Limekilns, Distillation Columns, Pressurized Reactor Vessels and a host of other applications where such profiles are necessary.

Multipoint assemblies can be miniaturized or they can be any length according to the specific requirement.

These assemblies generally consist of a Junction Box suitable for terminating the sensors and joining them to cables running back to the measuring instruments, the sensors arranged at various depths and a Pipe Protection well capable of resisting the pressures and corrosives in the vessel.

Free Hanging

Sensors are manufactured to the desired lengths, then bundles together with straps. The bundle is secured with a Clamp located in the Junction Box and hangs freely inside the Protection Tube. The measuring Junction absorbs the dead air temperature within the tube.

Spring Loaded

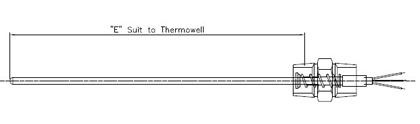

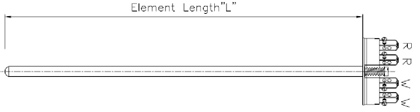

The flexibility or coiling capability of this design simplifies the installation and shipping. The Sensors are simply uncoiled and guided into a thermowell, thereby eliminating complex and costly installation methods usually prevalent in long length assembles. The spring Loaded construction ensures proper contact of the measuring junction with the thermowell inner wall for rapid response to any temperature change.

With Multitube

This design provides high Mechanical strength and thus can be used in High Pressure, High Temperature or extremely Adverse conditions. The sensors bottom on the measuring junction blocks which are integral parts of the thermowell wall providing high sensitivity to temperature change. Replacement of individual sensor can be accomplished quickly without without disassembling the entire unit.

Technical Information on Type of Thermocouples and its Limits

| Thermocouple Type | Chemical Compositon | Temperature Range Deg C | Std Limits of error whichever is greater | |

|---|---|---|---|---|

| +ve Leg | -ve Leg | |||

| E (Chromel Constantan) | Ni, 10%Cr | Cu, 45%Ni | 0 To 900 | +/-1.7Deg C or+/-0.5% |

| J (Iron Constantan) | Fe | Cu, 45%Ni | 0 To 750 | +/-2.2Deg Cor+/-0.75% |

| K (Chromel Alumel) | Ni, 9.2%Cr, 0.4%Si | Ni, 2.5%Si,Co1.2% | 0 To 1250 | +/-2.2Deg Cor+/-0.75% |

| T (Copper Constantan) | Cu | Cu,45%Ni | 0 To 350 | +/-1.0Deg Cor+/-0.75% |

| S | Pt | Pt, 10% Rh | 0 To 1450 | +/-1.5Deg Cor+/-0.25% |

| R | Pt | Pt, 13% Rh | 0 To 1450 | +/-1.5Deg C or+/-0.25% |

| B | Pt, 30% Rh | Pt, 6% Rh | 870 To 1700 | +/-0.5% |

Wire Size Versus Upper Service Temperature for Thermocouples.

| Type | 8 Gauge/ 3.25mm Diameter | 14 Gauge/ 1.63mm Diameter | 20 Gauge/ 0.81mm Diameter | 24 Gauge/ 0.51mm Diameter | 28 Gauge/ 0.33mm Diameter |

|---|---|---|---|---|---|

| E | 870 Dec C | 650 Deg C | 540 Deg C | 430 Deg C | 430 Deg C |

| J | 760 Deg C | 590 Deg C | 480 Deg C | 370 Deg C | 370 Deg C |

| K | 1260 Deg C | 1090 Deg C | 980 Deg C | 870 Deg C | 870 Deg C |

| N | 1260 Deg C | 1000 Deg C | 980 Deg C | 870 Deg C | 820 Deg C |

| T | 400 Deg C | 370 Deg C | 260 Deg C | 200 Deg C | 200 Deg C |

| S | -- | -- | -- | 1480 Deg C | 1480 Deg C |

| R | -- | -- | -- | 1480 Deg C | 1480 Deg C |

| B | -- | -- | -- | 1700 Deg C | 1700 Deg C |

Different Mountings of RTD’s and Thermocouples

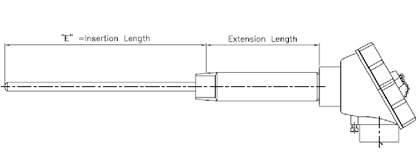

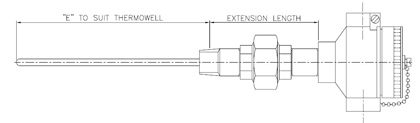

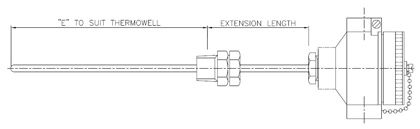

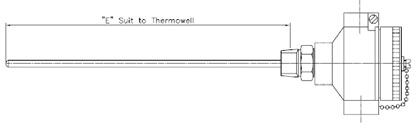

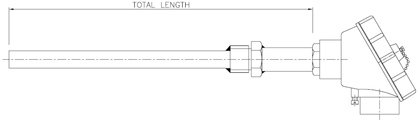

With Head Enclosure

Figure 1.

Figure 2.

Figure 3.

Figure 4.

Figure 5.

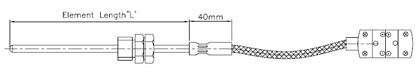

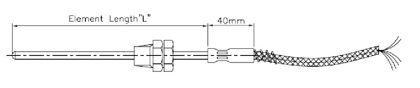

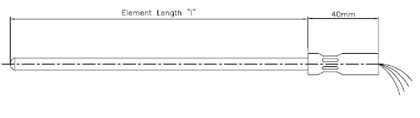

Without Head Enclosure

Figure 1.

Figure 2.

Figure 3.

Figure 4.

Figure 5.

Tests on RTD’s and Thermocouples.

Routine Tests

- Continuity Test

- Calibration

- Insulation Resistance Test at Room Temperature

- Insulation Resistance Test at High temperature

- N2 Test

- Response Time

Test Types

In-House Tests

- Repeatability Test

- Reproducibility Test

- Lead Pull Out Test

- High Voltage Test

- Self Heating Error Test

- Helium Leak Test for Weld Joints

- Rattling Test

- Autoclave Test

- Sheath Integrity Test

- Humidity- Temperature Chamber Test

Lab–Certified Tests

- Seismic Vibration Test

- Non Seismic Vibration Test

- Shock Test